Rooting for Mycelium

“Mycelium is Earth’s natural internet.”

— Paul Stamets

With the alternative protein landscape continuing to evolve rapidly, a quiet but powerful contender is quickly gaining ground given its ability to match the taste, texture, and nutrition of conventional meat across a multitude of applications. Mycelium is the root system of fungi, a complex network of threads called hyphae that grow beneath the soil. When these hyphae grow together in clusters, they form mycelium, which can be transformed into mycoprotein—an incredibly versatile ingredient packed with nutrients. Unlike mushrooms, which are the fruiting bodies of fungi, mycelia have a dense, meat-like texture and are rich in fiber, low in fat, and packed with essential amino acids.

The diversity of the fungal kingdom is vastly greater than that of the plant kingdom. The estimated number of fungal species (2.5 million) is about 7 times the number of known plant species (374,000). Of these, only about 10% have been explored, identified, and named by scientists thus far.1 The incredible variety of fungi also means that mycelium holds immense potential in the alternative protein market. As consumers increasingly seek sustainable, healthy alternatives, mycelium holds promise as the protein of the future.

Image Credit: Dmytro Ostapenko/Shutterstock

Magic Mycelium

Mycelium’s journey began long before the recent buzz, back in the 1960s, when a British company named Marlow Foods started research in the space. Two decades later, Quorn was formed in 1985 to commercialize mycelium as a meat alternative. Initially, the category was born out of a need to tackle food security and create a more sustainable protein source. Over time, it has evolved into a versatile, eco-friendly option, offering a sustainable solution to the world’s growing protein demands.

What makes mycelium so exciting? It ticks every box. Unlike plant-based proteins, which can be limited in texture and flavor, mycelium offers something truly unique. When grown under controlled conditions, its dense, fibrous structure delivers a satisfying chew that closely resembles traditional animal products like chicken or beef. This texture absorbs flavors well, making it incredibly adaptable for a wide range of dishes. Nutritionally, mycelium stands shoulder to shoulder with animal meat, providing all nine essential amino acids, but without the saturated fat and cholesterol. It is rich in glutamic acid, which contributes to its umami flavor, and is also rich in fiber, B vitamins, and minerals like iron and magnesium, making it a powerhouse for anyone looking for a balanced, complete protein source.

Beyond flavor and nutrition, mycelium is highly functional. It can be engineered to replicate meat in various forms—from the tender texture of pulled pork to the hearty bite of a steak. What’s more, mycelium is a truly circular solution as it can be grown on organic waste materials. It grows quickly (within days), making large-scale production feasible. This scalability, paired with its low environmental footprint, positions mycelium as a leading contender in the race to develop sustainable alternatives to traditional meat.2

Root to Table

The process of making mycelium protein is as fascinating as it is varied. There’s no one-size-fits-all approach; different strains of fungi may be utilized, each offering unique qualities from flavor to texture to nutritional content. For instance, Ganoderma lucidum, better known as Reishi, is celebrated for its health benefits and is often used in functional foods. While it grows on a variety of substrates, its slower growth rate makes it less ideal for large-scale protein production. In contrast, Trametes versicolor (Turkey tail) grows quickly and is often used for its medicinal properties, though it has less protein (around 10-20%) compared to other fungi.3 One of the most popular fungi for creating mycoprotein, however, is Fusarium venenatum. This strain is the workhorse behind Quorn products, renowned for its rapid growth, high protein content, and the meaty texture it produces.4 Another strain, Neurospora crassa, also boasts of impressive growth but hasn’t yet seen similar commercial success.

Once the right strain is selected, the next step is fermentation. The following are the dominant methods for growing mycelium:

Submerged fermentation involves growing mycelium in a nutrient-rich liquid medium, where it is carefully controlled for temperature and pH. This method enables consistent and efficient production but is not without its challenges. The process is energy-intensive, and the texture of the resulting mycoprotein tends to be softer, making it less meat-like. On the plus side, submerged fermentation can produce a protein yield of up to 30-40% of the dry biomass, depending on the strain.5

Solid-state fermentation involves mycelium growing on solid substrates, such as agricultural waste or grains. This method is environmentally friendly because it utilizes waste products, creates a circular system, and requires less energy for aeration. The texture of the end product tends to be more fibrous and meat-like, making it ideal for alternative meats. However, it has some drawbacks: it yields less protein and can be challenging to control at scale. The quality of the substrate plays a crucial role in determining the consistency of the final product, and large-scale fermentation can result in uneven outcomes.6

Liquid surface culture fermentation is a lesser-known method where mycelium grows on the surface of liquid media in shallow trays. This method is effective for producing dense, protein-rich fungal structures while being energy-efficient as it requires less external oxygen. The downside? The growth is often uneven, the final texture is harder to control, the collection and downstream purification process can be tedious, and the longer fermentation time can make output less consistent.7 Nature’s Fynd developed a unique application of this methodology called liquid-air interface fermentation to produce their mycelium-based protein ingredient, Fy.

Gas fermentation utilizes large bioreactors that promote mycelium growth through optimal gas exchange and aeration. The high oxygen content in the bioreactor acts as a catalyst, accelerating mycelium growth and yielding higher quality and quantity of biomass through a continuous process. However, the downside is that the system can be highly complex, requiring multiple different expensive infrastructure components to work in tandem. Additionally, the energy costs can be high unless the process is optimized using waste industrial gases or direct air capture methodologies.8

No conversation on fermentation methods is complete without discussing Quorn’s proprietary technology. Quorn developed a tailored process that utilizes submerged fermentation with a continuous flow culture system, called airlift fermentation, to produce its mycoprotein. The process uses large air-lift fermenters, which differ in design from conventional stirred-tank bioreactors. These fermenters benefit mycelial production by reducing shear stress, thus fostering longer hyphal growth, which is essential for replicating the texture of meat.9

Peaks and Pitfalls

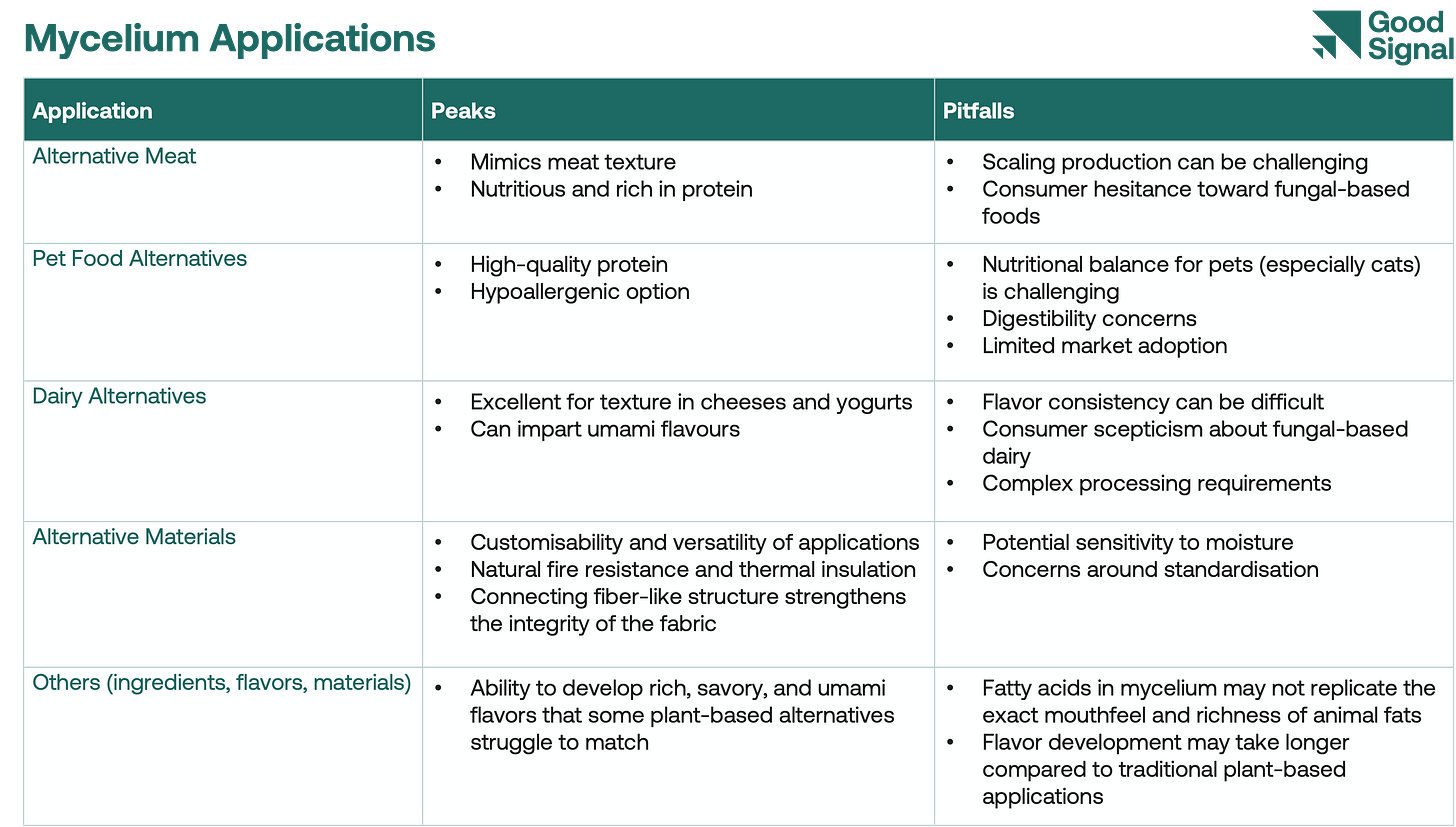

The use of mycelium is mushrooming (pun intended) across multiple applications. While it is early yet, the platform shows incredible potential for transforming the future of food. Several applications show promise.

Alternative Meat

Mycelium’s ability to mimic the texture of animal muscle tissue makes it perfect for alternative meats. Fermentation enhances the meatiness, creating a fibrous bite, using fewer resources, and emitting less carbon than traditional meat production. The challenge lies in scaling production and overcoming consumer skepticism about fungi and fermentation-derived foods.

Pet Food

Rich in protein, fiber, and essential amino acids, mycelium provides a nutritious alternative to conventional pet food. Although it is clearly a sustainable option, the challenge is meeting the specific nutritional needs of pets, especially obligate carnivores like cats, who need animal protein for optimal health. It is gaining traction as companies racing to bring products to market are turning to the pet food industry where regulations are more relaxed.

Dairy Alternatives

Mycelium’s binding and gelling properties replicate the creamy texture of cheeses and yogurts while also offering rich, umami flavors. The challenge is recreating the complex flavor profiles of traditional dairy products, particularly aged cheeses.

Alternative Materials

Mycelium can be used to develop a wide range of products, including building materials, packaging, furnishings, textiles, and even leather alternatives. Benefits offered by mycelium composites include fire resistance and natural thermal insulation.

Red Tape, Green Light

The regulatory landscape of mycelium-derived products varies as some nations embrace its use while others evaluate its safety and potential. In the United States, the Food and Drug Administration (FDA) has issued a few approvals to mycoprotein companies such as a 'no questions' letter issued for The Better Meat Co.'s Rhiza mycoprotein, and Generally Recognized as Safe (GRAS) status awarded to The Protein Brewery’s Fermotein.

The process in Europe is slightly different. Under EU regulations, any food that was not consumed ‘significantly’ before May 1997 is considered a novel food and requires pre-market authorization. Quorn’s Fusarium venenatum strain has been approved for food use in the EU since the 1980s, following extensive safety assessments by the European Food Safety Authority (EFSA). The European Commission also granted Novel Food status to MycoTechnology's FermentIQ MLL (milled) and PTP (protein powder) formats.

In Asia, Singapore leads with approvals also given to The Better Meat Co. and The Protein Brewery. South Korea could offer an attractive regulatory pathway as it considers certain mycelium-derived proteins and ingredients to be mushroom-related (depending on the origin of the strain). This can shorten the regulatory cycle as particular strains may not require approval, but rather a food safety analysis.

As the popularity of mycoproteins grows, countries will inevitably update their regulations to accommodate new fungi-based ingredients, balancing innovation with consumer safety.

Myco-Scope

As mycelium-based innovations continue to grow, the stories of companies navigating this space reveal both challenges and triumphs that have shaped their journeys. From product development to regulatory hurdles, these companies provide valuable lessons learned along the way.

Innovation – Libre Foods

Libre Foods took an innovative approach by focusing on whole-cut animal product alternatives. Their flagship product, a mycelium-based whole-cut chicken breast, became the first of its kind in the EU. The company highlighted the natural fibrosity of mycelium as the key to creating a clean-label product with fewer ingredients. But even with this breakthrough, the company faced regulatory challenges. Their initial bacon product stalled, forcing them to pivot to using the sprouting bodies of mushrooms for their products rather than the roots. To accelerate development and overcome hurdles, Libre developed a cutting-edge screening platform that combines robotics and machine learning to optimize fungi-based applications. "Mycelium is a blank canvas for endless product possibilities," said their CEO, underscoring the company’s belief in the future potential of mycelium.

Regulation – Infinite Roots (formerly Mushlabs)

For Infinite Roots, the initial pull to mycelium lay in its complex aroma, which made it well-suited for a wide range of applications, especially as a meat alternative. Mycelium’s properties, which closely mimic animal meat, mean less processing is required. However, the journey to market was far from smooth, particularly when it came to regulatory approval. Initially targeting Europe, the company encountered a lengthy, slow regulatory process. As one team member put it, “This can easily turn into a couple of years of documentation and finding the right labs.” Eventually, Infinite Roots found success by partnering with Pulmuone in South Korea, overcoming its regulatory challenges to find a path forward.

Scale-up – Ecovative

Ecovative has focused on using mycelium for sustainable materials to partner with ECCO to produce ECCO Leather, a cruelty-free leather alternative. The company’s attraction to mycelium lies in its circularity and natural recycling properties. However, scaling up production posed significant challenges. Production downtime and operational inefficiencies were key hurdles, leading Ecovative to learn from the Dutch mushroom farming industry to improve scale-up processes. Armed with insights from an established industry, the company optimized its AirMycelium platform, enabling it to expand into food- and fashion-related applications.

Product Market Fit – Nature’s Fynd

From the outset, Nature’s Fynd positioned the Fy ingredient as an ingredient with a myriad of applications. The outcome was both a meat and dairy alternative. The company’s CMO highlighted that it took extensive quantitative work, to understand which products had consumer appeal. For example, kombucha is also made from microbes but has only gained popularity in recent years after the nutrient density of the product was placed front and center in easily accessible formats.

Market Expansion – Quorn

Quorn, the leader in mycoprotein-based alternative meat, faced a different challenge—market positioning and expansion. After being acquired by Monde Nissin in 2015, Quorn’s focus shifted toward differentiating their mycoprotein products not only from plant-based alternatives but also from conventional meats. As Quorn’s CEO noted, "Benchmarking is useful, but when you're creating something new, it comes with its own set of challenges." To stay ahead, Quorn has focused on creating a distinct identity, educating consumers on the benefits of mycoprotein, and reinforcing its position as a leader through strategic acquisitions for geographic expansion.

As the industry continues to evolve, the lessons learned from its pioneers will help shape the future of mycelium in food and beyond. The alternative protein industry has come a long way, but there is still “mush-room” for growth.

New Phytologist Foundation

Wageningen University and Research

Mushroom Research Center Austria

Quorn

Moore (2019), 21st Century Guidebook to Fungi

Anupama and Ravichandran (2012), Solid state and submerged fermentation for the production of bioactive substances: a comparative study

Darouneh et. al. (2009), Citric acid production: Surface culture versus submerged culture

Holt et. al. (2023), Mycelium: A nutrient-dense food to help address world hunger, promote health, and support a regenerative food system

Ritala et. al. (2017), Single Cell Protein – State of the art, industrial landscape, and patents 2001-2006

Wahoo you're back!